- CC2500 needs a power cycle to reset it ? (Like blue smirf)

- Library changes don't always get picked up by Arduino (like Wixel)

I had RSSI in the -50's, now they're in the -70's.

Originally I had the bare minimum for register settings, then I slowly added additional ones. Living life in 5 minute increments. Biggest improvement was setting the bandwidth slightly below the 335 khz that Dexcom wants. RFStudio will choose a value of 400 khz, the other increment available is 325. 325 made a huge difference.

So, I'm back to the minimum and testing one value at a time.

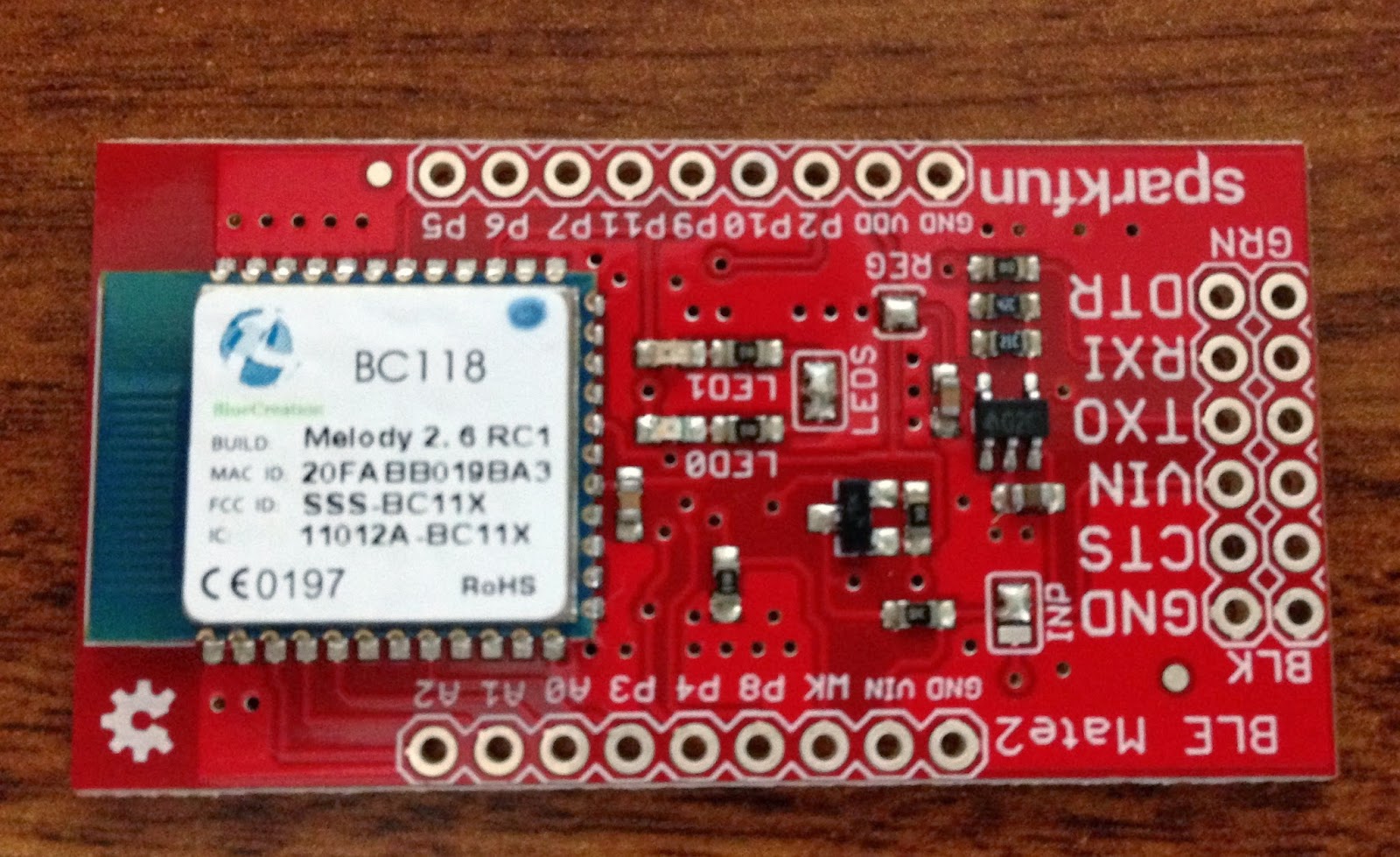

This will allow me to experiment with Central role BTLE. And, someone has cracked the Nike Fuel band, See->http://hackaday.com/2015/01/30/hacking-the-nike-fuelband/

This might make a good display device, and it appears to take a bitmap for that display, like the MetaWatch. So maybe, we can talk directly to it and leave the Phone at home.

News alert, RSSI's back in the 60's, just by changing the "TEST" registers. Isn't that great, if you call something "TEST", should it have any real purpose? Noooooo. Thank you TI.

Almost time to head to the gym to hit people. My best test environment. Something there shuts down the Dexcom (antenna symbol) and my custom devices.